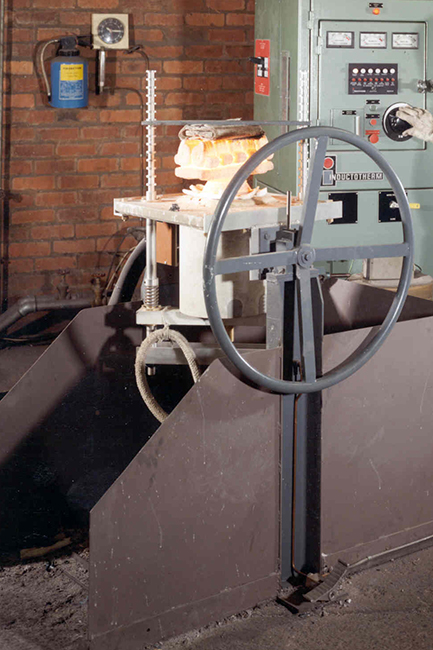

Rollover Furnaces are ideal for close control of pouring and metal quality to produce high-end investment castings.

With Rollover Furnaces, charge size can be accurately controlled and molds filled completely due to the added force obtained during rollover. These furnaces consist of an induction furnace on a rotating frame. When the pre-weighed charge is fully molten, a heated mold is clamped over the furnace and the entire assembly is rolled over, filling the mold which is then upright. There is reduced incidence of refractory inclusions because the metal transfers directly into the mold with minimum refractory contact. The entire melt and pour cycle can be accomplished under inert atmosphere conditions for enhanced metal quality. The rollover mechanism accommodates a variety of furnace sizes. These compact solid state units provide fast, “hands off” operation at maximum efficiency. The furnaces are constructed to give maximum protection to the induction coil and to provide a furnace top and body high mechanical strength to withstand mold clamping stress.

Infographic

Infographic

Literature

Literature

Article

Article