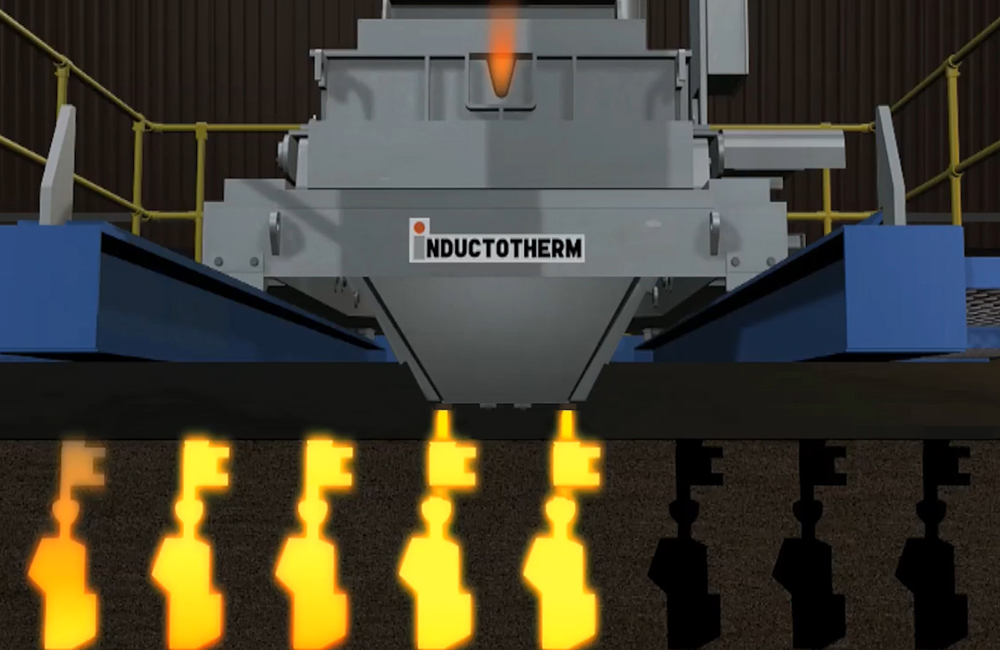

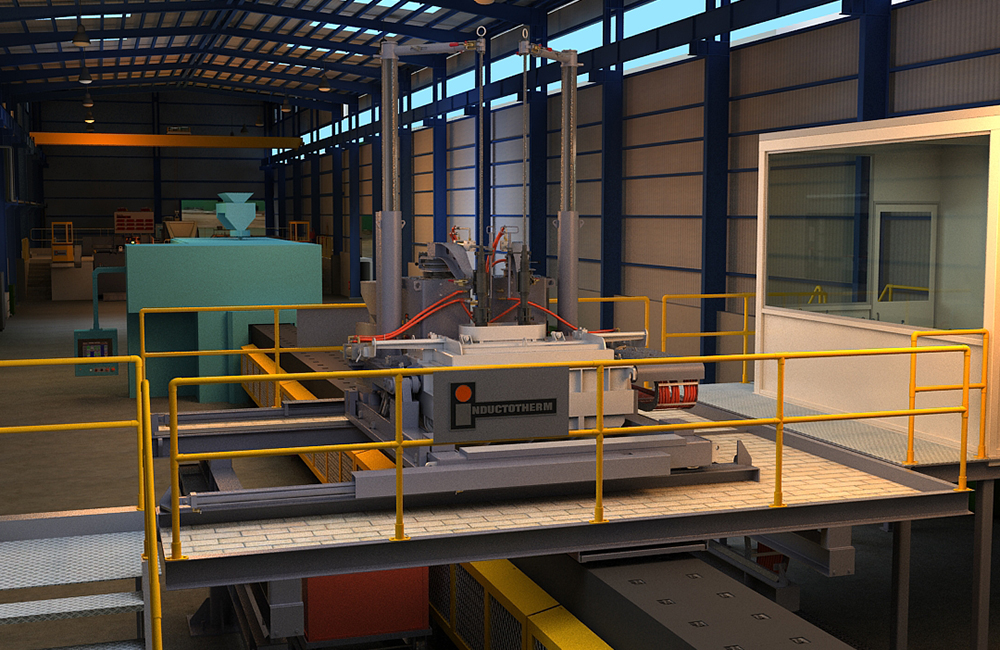

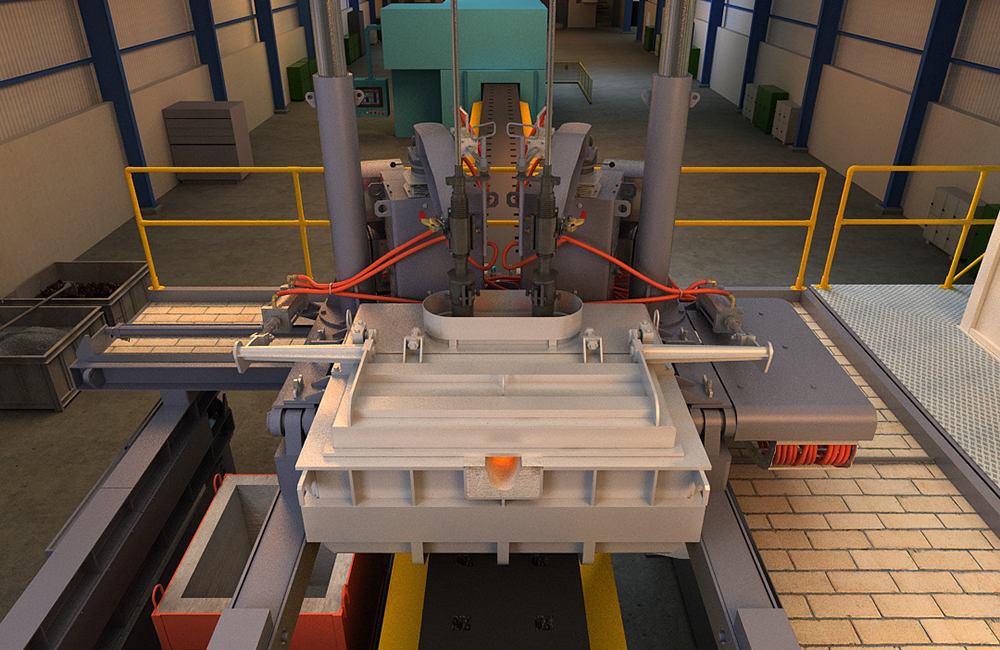

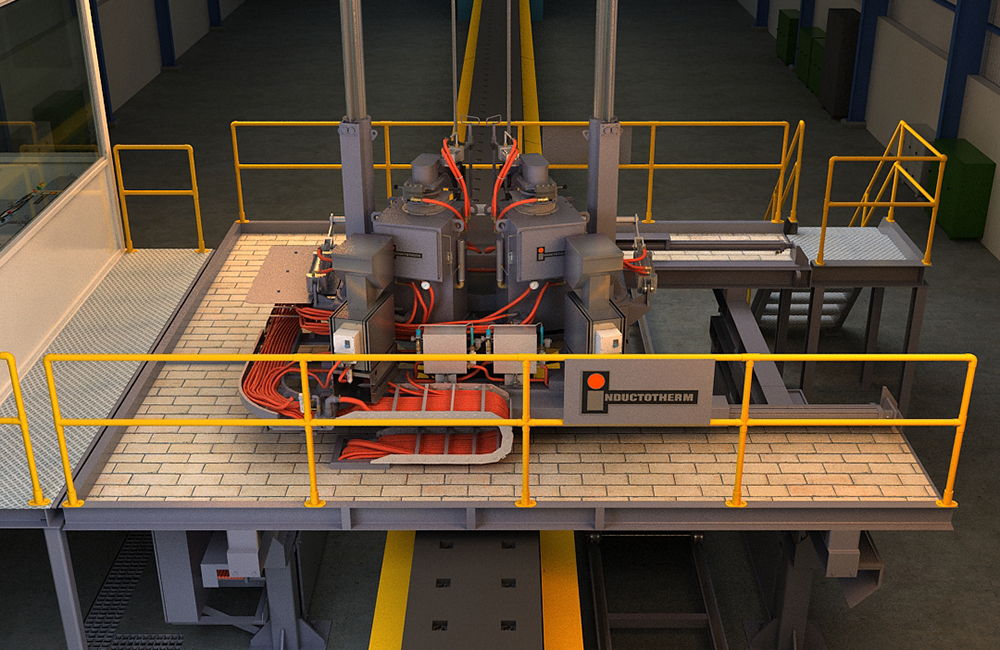

MULTI-POUR™ Systems

Our patented MULTI-POUR™ Automated Pouring Equipment and Technology truly allows you to keep pace with the fastest molding machines for accuracy, repeatability and reliability.

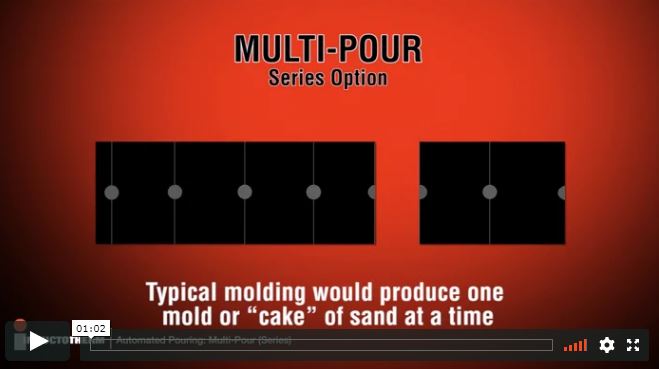

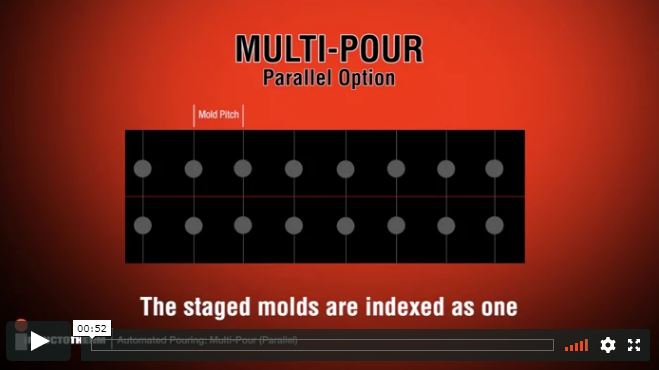

Foundries that require the fastest Automated Pouring System on the market today choose MULTI-POUR™ Technology to handle molding machines that transfer two molds simultaneously. MULTI-POUR™ Automated Pouring Systems feature our advanced VISIPOUR® P³® (Predictive Pour Performance) Control Technology and utilize two or more adjustable vision-based cameras and two or more adjustable stopper rod systems to effectively pour each mold line from the same vessel or from separate vessels, depending on your application. This recent breakthrough delivers the most precise pouring control with the fastest production rates. Available for either series or parallel pouring, these systems are the most advanced in the field.

Features

| Standard Features | Optional Features |

|---|---|

| Bottom Pour Stopper Rod Pouring | X-Y Axes Motion |

| Adjustable Vision-Based Cameras | Stopper-Rod Pouring Control Systems |

| Pneumatic Charging Cover | |

| Hydraulic Tilting |

Tech Specs

| Capacities | Factory Tested |

|---|---|

| 2 to 5 Metric Tons [2.5 to 5.5 Short Tons] | Critical Components |

| Click here to contact Inductotherm for Custom Solutions |

Control Options

VISIPOUR® P³® (Predictive Pour Performance) Control Technology is our breakthrough advancement in Automated Pouring and provides perfect pour precision. The enhanced nature of our advanced VISIPOUR® P³® (Predictive Pour Performance) Control Technology not only reduces pour times for individual molds, but can also run multiple mold filling applications because it suits a wider variety of pouring possibilities.

Article

Article