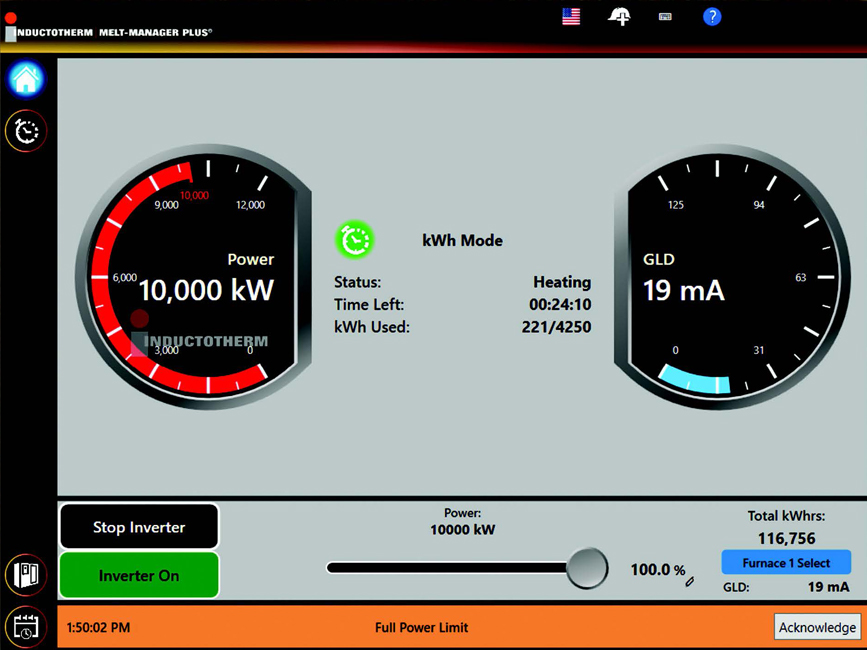

Melt-Manager® Plus® Control Systems

Melt-Manager® Plus® Control Systems provide a higher level of melt automation technology to support furnace melt controls, diagnostic analysis and customer network, and communication interface.

Melt-Manager® Plus® Control Systems are computer-based applications that are formatted for touch-screen, flat-panel computers, and provide an “easy to use” graphic interface, where most screens are accessed with a single touch. The graphic screens will assist the operator throughout the complete melting process.

Melt Control Modes for kWh Melting:

Assists in accurately reaching the desired pouring temperature with hold-power setting; optimizes power usage and reduces electric utility charges; includes cold start scheduling for pre-heating the furnace to improve production efficiency, and for sintering, for reducing manpower requirements and improving lining life.

Data History and Trending:

Provides automatic collection of operational data that can be displayed on trend charts to provide operators and managers with a graphical rendering of the melt system’s daily operational history.

Events and Alarm Logging:

Records and displays the system’s alarm and events history from a date calendar, providing operators and managers with a clear view of daily operations, making it easy to identify utilization factors, overall production efficiency and any operational delays.

Diagnostic Screens:

Offers complete system I/O signal diagnostic information available via a comprehensive color coded screen to explore troubleshooting processes and provide inverter information and communications activity.

Ethernet Industrial Protocol:

For customer systems to gain access to melt process run-time and diagnostic data formatted for PLCs and Host Computer Systems.

Features

| Standard Features |

|---|

| Formatted for Operator-friendly, Color Touch-Screen, Flat-panel Computers |

| Monitors, Displays and Records the Power Supply Meter Readings |

| Displays and Records System Events and Alarms |

| Automated Control of the Complete Melt Cycle |

| Displays and Records Melt Control Operating Status |

| Schedule Input for Automated Cold Start Control |

| Permits Heating Profile Input for Automatic Lining Sintering |

| Calculates Furnace Inductance for Lining Condition Estimate |

| Comprehensive Diagnostic Checks |

| Provides Event Information Associated with Incoming AC Line Voltage |

| Provides Event Information to Alert Users to Potential Arcing Situations |

| Includes Built-In Safety Features to Maintain Proper Operation |

| Maintains Record of Kilowatt Hours Used |

| Provides Daily Data Log Files for Metering, Alarms, Events and Inductance |

| Text Messaging Option for Selectable Melt Control Status, Alarms and Events |

| Temperature Monitoring Interface |

| Advanced Sensors Network Interface |

| Ethernet Industrial Protocols Interface |

| Computer Networking Over Ethernet |

| Multi-Language Support |

Tech Specs

| Factory Tested |

|---|

| Critical Components |

Melt-Monitor™ System

Inductotherm’s optional Melt-Monitor™ system provides data display and data reporting only without the control and interactive features available to the melt operator when using the Melt-Manager Plus® operating control system. This system is ideal for the monitoring of melt operation from local or remote locations via Ethernet or dial-up. Now you can check out your melt shop’s performance, whether it is located around the corner, in a different state or on a different continent.

Literature

Literature