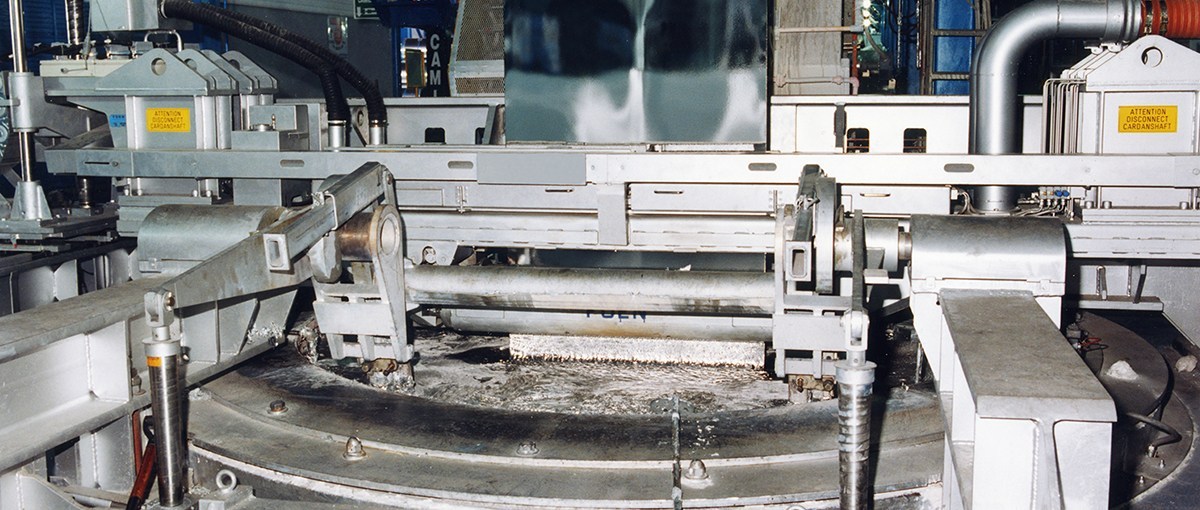

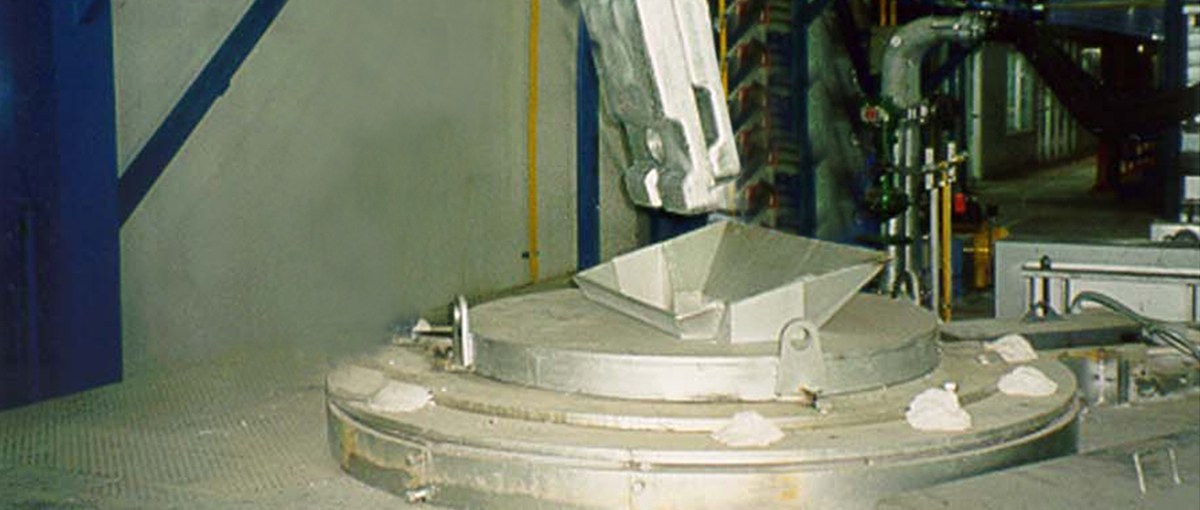

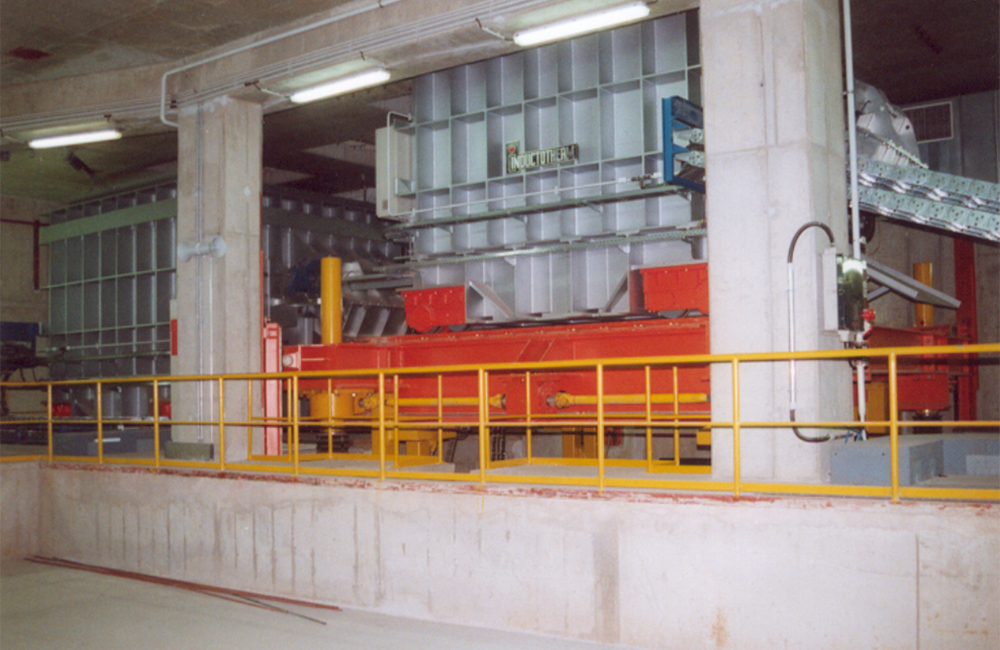

Channel Coating Pots

Channel Coating Pots provide good inductor refractory life making them ideal for galvanized, galvannealed and Galfan® coatings. They are also used for aluminum zinc and other aluminum alloy coatings. Inductotherm Channel Coating Pots are used by the steel industry for the continuous coating of steel strip.

LEARN MORE

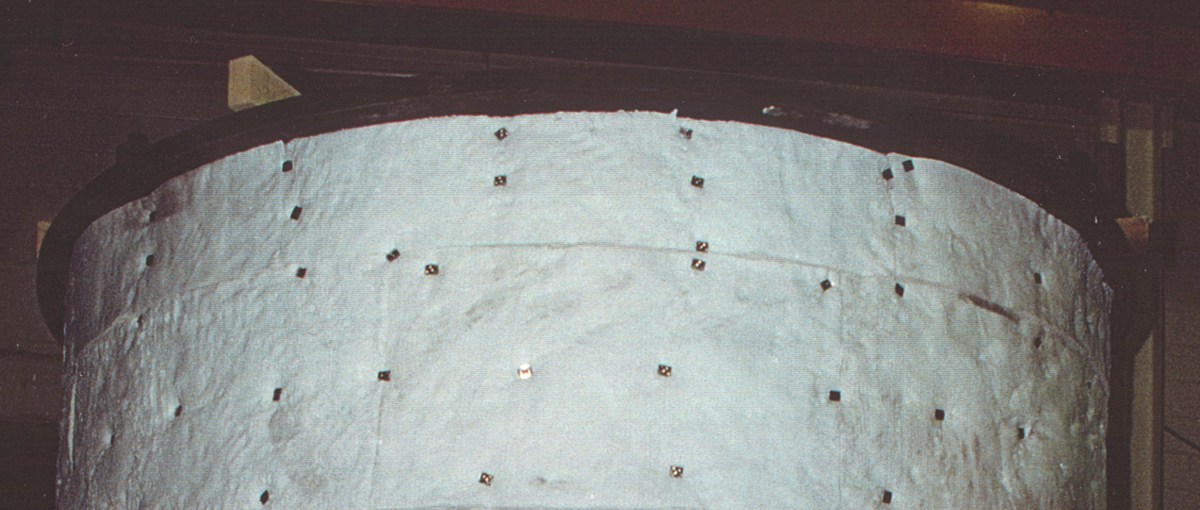

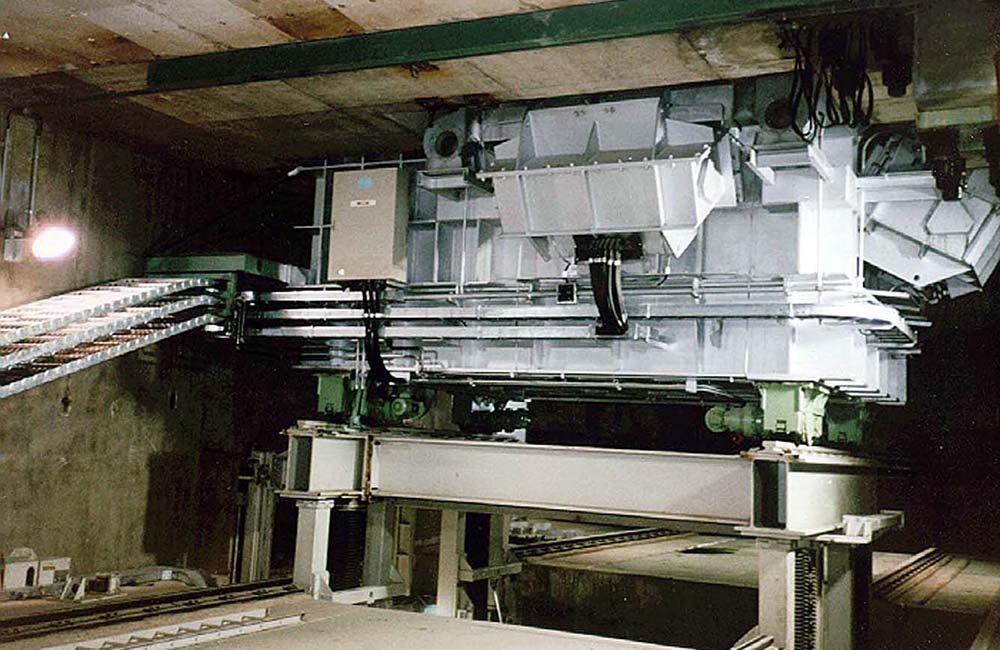

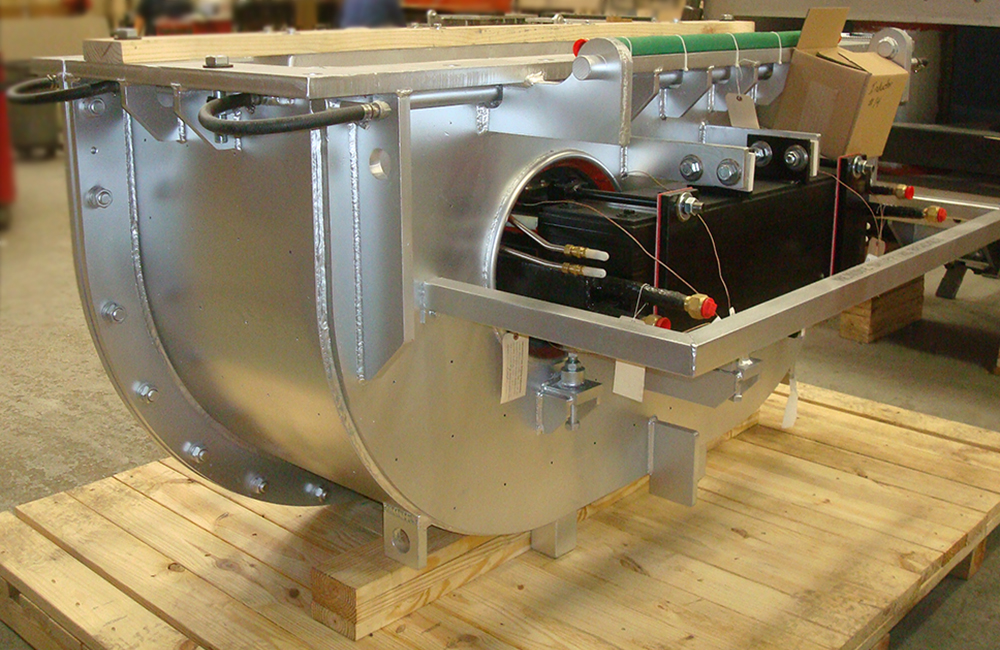

Channel Coating Pots provide good inductor refractory life making them ideal for galvanized, galvannealed and Galfan®coatings. They are also used for aluminum zinc and other aluminum alloy coatings. Channel inductors contain induction coil assemblies and a magnetic core made of special transformer sheet laminations. These pots are designed to hold very large volumes of metal. Inductotherm Channel Coating Pots feature:

- A rectangular design accommodates large volumes for direct ingot feeding

- Heavy gauge steel plates provide excellent refractory support

- Temperature monitoring to enhance reliability

- On-site preparation with custom dry rammed refractory around a consumable channel mold (can be hung within 24 hours of installation)

- Optional bogies and lifts for multiple pot installations

- Water-cooled or air-cooled inductors

Galfan® is a trademark of Galfan Technology Centre, Inc.

Features

| Standard Features | Optional Features |

|---|---|

| Water-Cooled Twin Loop Inductors up to 750 Kilowatts | Metal Level Measurement and Monitoring |

| Air-Cooled Twin Loop Inductors up to 500 Kilowatts | Remote Control Consoles for Remote Operation from a Central Pulpit |

| Hybrid Water and Air-Cooled Inductors up to 500 Kilowatts | PLC Controls and Communication Options Available on VIP® and VIP-I® Power Supply Units |

| Inductor Flange Metal Leak Detection | Emergency Power and Changeover Systems |

| Single-Phase Tap Changer Power Supply Units up to 500 Kilowatts | Inductor Covers |

| Three-Phase Balanced Tap Changer Power Supply Units up to 500 Kilowatts | Insulated Pot Covers |

| Solid-State VIP® Power Supply Units with SCR Technology up to 750 Kilowatts | Moveable Pot Designs for Multi-Pot Installations |

| Solid-State VIP-I® PWC Power Supply Units with IGBT Technology up to 500 Kilowatts | Pot Lifting Systems for Multi-Pot Installations |

| Water Cooling Systems with Emergency Backup | Automated Robotic Dross Removal Provided by the ARMS® System |

| Molten Metal Leakage Detection | |

| Power Pulsing Circuit | |

| Patented Hollow Metallic Channel Mold for Zinc and Zinc-Aluminum Alloy Applications |

Tech Specs

| Capacities | Factory Tested | Available Retrofit Options |

|---|---|---|

| Large Capacity Continuous Coating Lines | Critical Components | Molten Metal Leakage Detection |

| Small Capacity Hot-Dip Batch Coating | Communications Options via a Variety of Industrial Protocols | |

| Power Pulsing Circuit | ||

| Automated Robotic Dross Removal Provided by the ARMS® System |

Literature

Literature