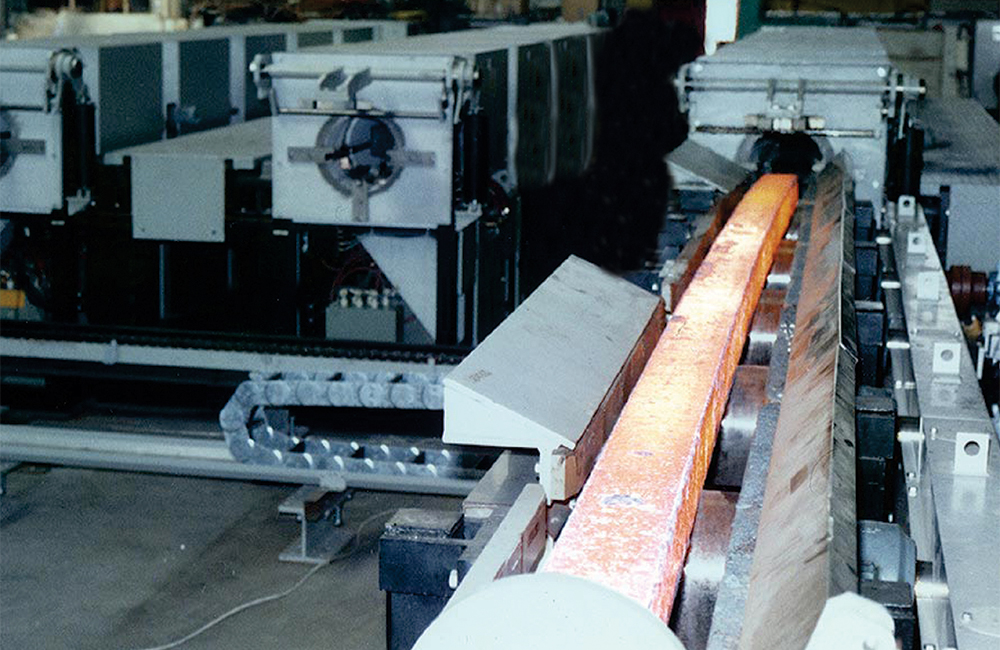

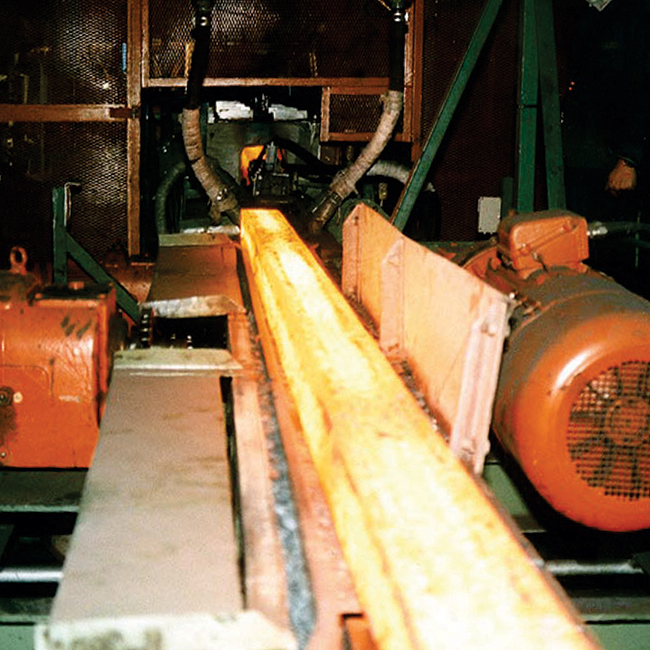

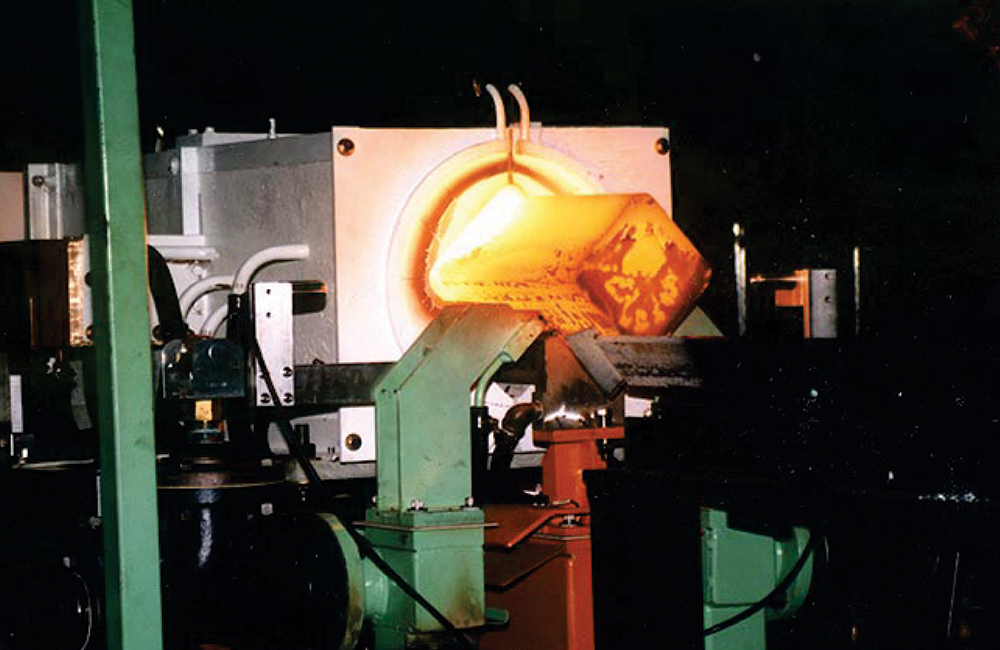

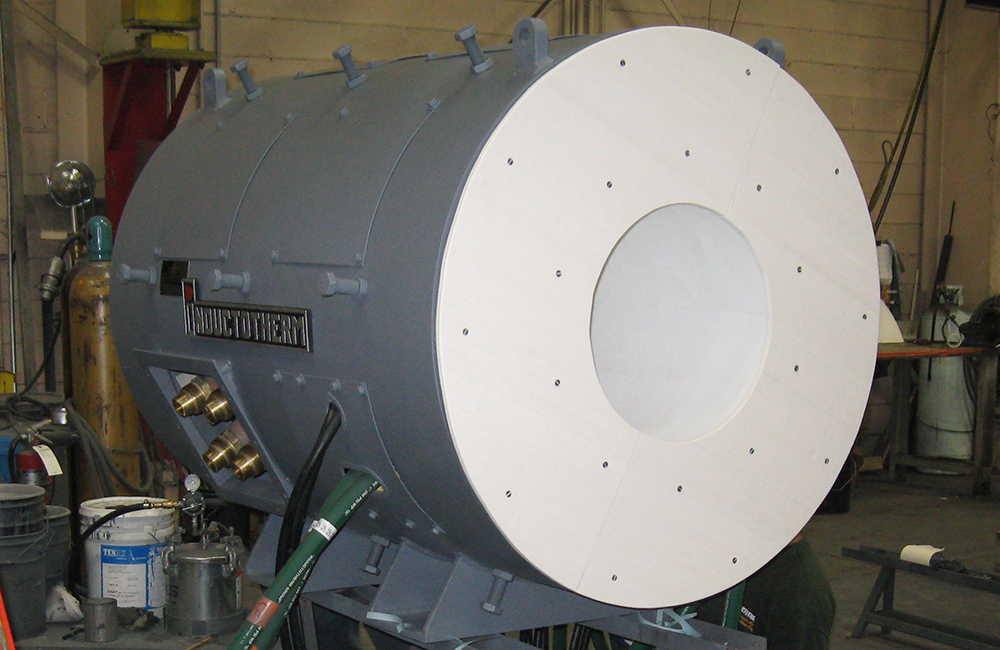

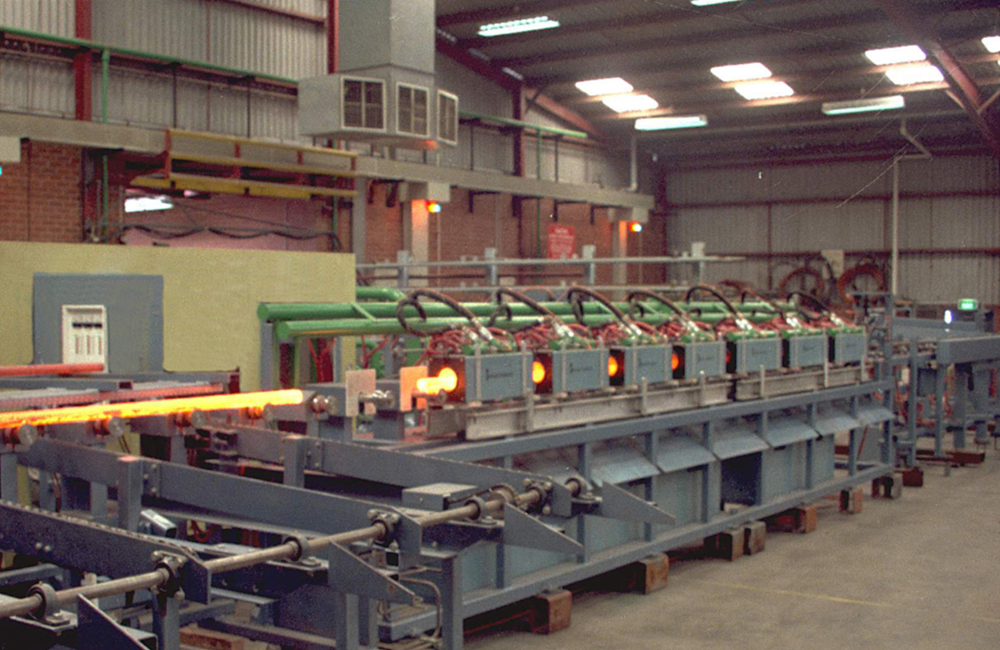

Bar, Bloom and Billet Heating Systems

Inductotherm high-power density induction systems provide mill operators with the most efficient and cost-effective technology for bringing bars, blooms and billets to optimum temperature prior to a forming, rolling or forging operation. Bar, Bloom and Billet Heating Systems use high-efficiency, electro-magnetically shunted heating coils which are supplied with electrical energy by high-efficiency, solid-state power units.

Features

Bar, Bloom and Billet Heating Systems use high-efficiency, electro-magnetically shunted heating coils which are supplied with electrical energy by high-efficiency, solid-state power units. Before a bar, bloom or billet moves from the continuous caster to the rolling mill, it must be reheated. Our systems provide the rolling mill with a continuous supply of uniformly heated billets, bars and blooms at the proper temperature which is crucial to efficient mill operations. Inductotherm induction heating systems offer:

- Temperature equalization for continuously cast billets

- Temperature control and consistency

- Modular design for quick coil change to accommodate for different sizes

- Level control to centralize all bar sizes in coil opening

- High-efficiency, solid-state power units

- Fully automated, PLC controlled material handling systems

- Available in frequencies between 60 and 10,000 hertz