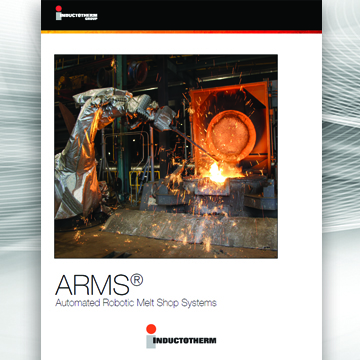

ARMS® Systems

ARMS® Systems offer safety advantages that no other product on the market can currently match.

The Inductotherm ARMS® (Automated Robotic Melt Shop) System is a patented concept that uses a robot to perform the hazardous operations that would otherwise be handled by a furnace operator, allowing the melt deck worker to be relocated to the control room. This greatly improves worker’s safety, recruitment and retention.

Click here to watch the ARMS® System in action!

Operations performed by the ARMS System robot include:

- Checking the metal bath grounding

- Dipping the thermocouple lance

- Taking metal samples

- Adding any required trim materials

In addition to performing many operational tasks, these automated systems are available to efficiently remove slag using a clamshell slagger. This allows the melt deck operator to run melt shop operations away from the area closest to the furnace, significantly improving worker safety and comfort which can help with employee retention. Using the ARMS® Systems can greatly speed slag removal from the bath in larger furnaces.

Features

| Standard Features | Optional Features |

|---|---|

| Slagging of the Furnace Bath | Clamshell Slagger and Slagger Stand |

| Checking the Bath Ground Probes | Starter / Control / Disconnect Box |

| Taking Metal Samples | Coagulant Dispensing Systems |

| Adding Trim or Coagulant Material | |

| Providing Video Feedback (Overview, Furnace Bath and Pouring) | |

| HMI (Human-Machine Interface) Control Desk | |

| “Smart” Tool Rack | |

| Molten Metal Depth Measurement Device | |

| Video Systems | |

| Melt Deck Operations Control Desk |

Tech Specs

| Lifting Capacities | Furnace Configurations | “Smart” Tool Rack Selections | Factory Tested |

|---|---|---|---|

| 30 to 500 Kilograms [66 to 1100 Pounds] | Contact Inductotherm for Custom Solutions | Slagging Tool | Critical Components |

| Thermocouple Tool | |||

| Sample Tool | |||

| Bath Grounding Probe | |||

| Trim Material Pan | |||

| Sample Spoon Tool | |||

| Thermocouple Tips | |||

| Metal Sampling Lances |

Accessories

The Inductotherm ARMS® (Automated Robotic Melt Shop) System has a variety of accessories that can be sold as part of the system or incorporated separately such as:

Clamshell Slagger Systems:

Slag is often an unavoidable by-product of melting metal. The process of removing slag from large furnaces can be a time consuming and labor intensive operation which can expose furnace operators to high levels of radiant heat and physical exertion. Therefore, as induction furnaces grow larger and melt faster, efficient and operator friendly removal of slag becomes more important. Clamshell slagging systems are one way slag removal can be accomplished. These systems can be used with Inductotherm’s ARMS® System or operated from an overhead or jib crane.

Inductotherm Melt Deck Video Systems:

Whether you want to see an approaching cold ladle or a perfect birds-eye view of your material handling/charging system–Inductotherm’s Melt Deck Video System can work for you. Inductotherm uses CCTV industry standard components which are mounted on individual frames that allow for tilting to get the optimum viewing angle and reach to ensure a consistent image. The video control box provides power to multiple cameras while simultaneously receiving video signals back from each camera and rerouting the signal to its respective monitor. Depending on your individual needs, Inductotherm can also supply camera mounting poles, powered dark shade lenses for viewing white-hot pours into ladles, video monitor mounting frames and video selector switches for sharing monitors.

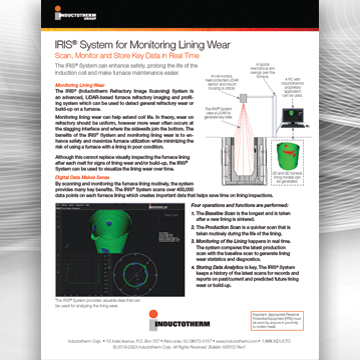

IRIS®

(Inductotherm Refractory Image Scanning) Systems:

The IRIS® (Inductotherm Refractory Image Scanning) System is an advanced, laser-based furnace refractory imaging and profiling system which can be used to detect general refractory wear or build-up on a furnace. It can often enhance safety, prolong the life of the induction coil and make furnace maintenance easier. Key operations and functions include a baseline scan after a new lining is sintered; a production scan taken routinely during the life of the lining; monitoring of the lining in real time and storing data analytics for records/reports for predictive lining wear or build-up. This system can also be used with Inductotherm’s ARMS® System or added to a melt deck in a number of custom configurations.

Infographic

Infographic

Literature

Literature

Article

Article