VIP® Multi-Switch™ Power Supply Units

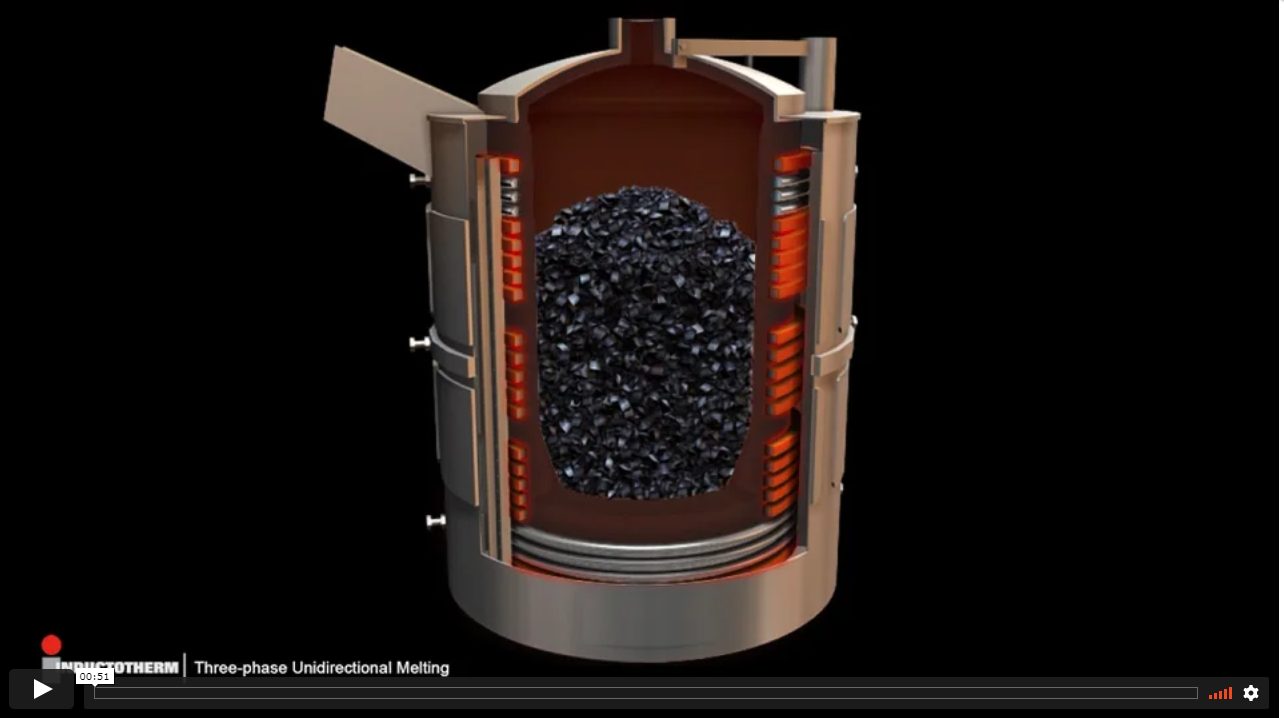

VIP® Multi-Switch™ Induction Power Supply Units provide full and precise zoned temperature control for graphite heating applications.

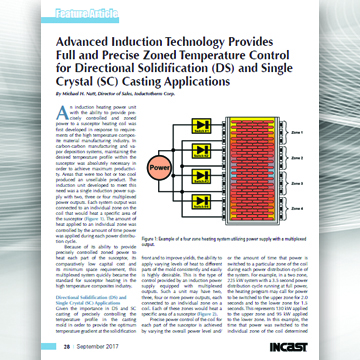

These units closely control the desired temperature over the entire hot zone with two or more multiplexed power outputs. These power outputs heat separate sections of the susceptor independently to provide full and precise zoned temperature control for a wide variety of high temperature controlled atmosphere heating and sintering operations. With multiple power switching technology, we offer the ability to control the power applied to each zone of the susceptor to achieve complete flexibility.

Additional advantages include:

- The option to apply greater power to the bottom zone of the susceptor than to the top zone or zones

- The ability to put a temperature “burst” into any zone of the susceptor directly

- Zone control typically reduces overall process time

- Improved efficiency as the system uses only the power needed for induction heating

- Variable switching time to meet any application

Features

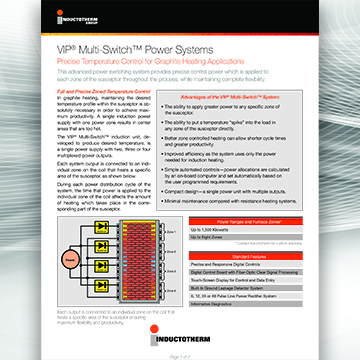

| Standard Features | Optional Features |

|---|---|

| Precise and Responsive Digital Controls | System Status Text Messaging |

| Digital Control Board with Fiber-Optic Clear Signal Processing | Melt-Manager® Plus® Control Systems |

| Touch-Screen Display for Control and Data Entry | |

| Built-In Ground and Leak Detector System | |

| 6, 12, 24 or 48 Pulse Line Power Rectifier System | |

| Informative Diagnostics |

Tech Specs

| Power Ranges | Furnace Zones | Factory Tested |

|---|---|---|

| Up to 1,500 Kilowatts | Up to Eight Zones | Critical Components |

| Click here to contact Inductotherm for Custom Solutions |

Control and Safety Options

Melt Shop Control Systems enable you to take control by monitoring and controlling the melt, diagnosing faults, maximizing power usage, minimizing power/fuel charges and performing a variety of tasks. We offer a variety of control system options which include:

- Melt-Manager® Control Systems are our entry level to smart systems that utilize embedded microprocessor controls and provide the operator with melt control modes and diagnostics for analysis and support.

- Melt-Manager® Plus® Control Systems are computer-based applications which provide a higher level of melt automation technology to support furnace melt controls, diagnostic analysis and customer network, and communication interface.

- Meltminder® 300™ Melt Shop Control and Management Systems provide the highest level of melt automation technology to support precise, highly responsive and fully programmable control, which is important to the safe and efficient operation of today’s induction melting equipment.

Safety Options and Retrofits are critical for guarding your equipment against possible failures. To improve each units overall efficiency and safety, Inductotherm provides options that can be retrofitted as needed to provide you with the most advanced equipment without replacing entire units, which include:

- AC Line Spike Suppressors protect your induction power supply unit from electrical power surges. It provides built-in protection from a range of incoming electrical spikes. The important protection offered by the AC Line Spike Suppressor is available on new equipment and can also be retrofitted to most existing power supplies.

Literature

Literature

Article

Article