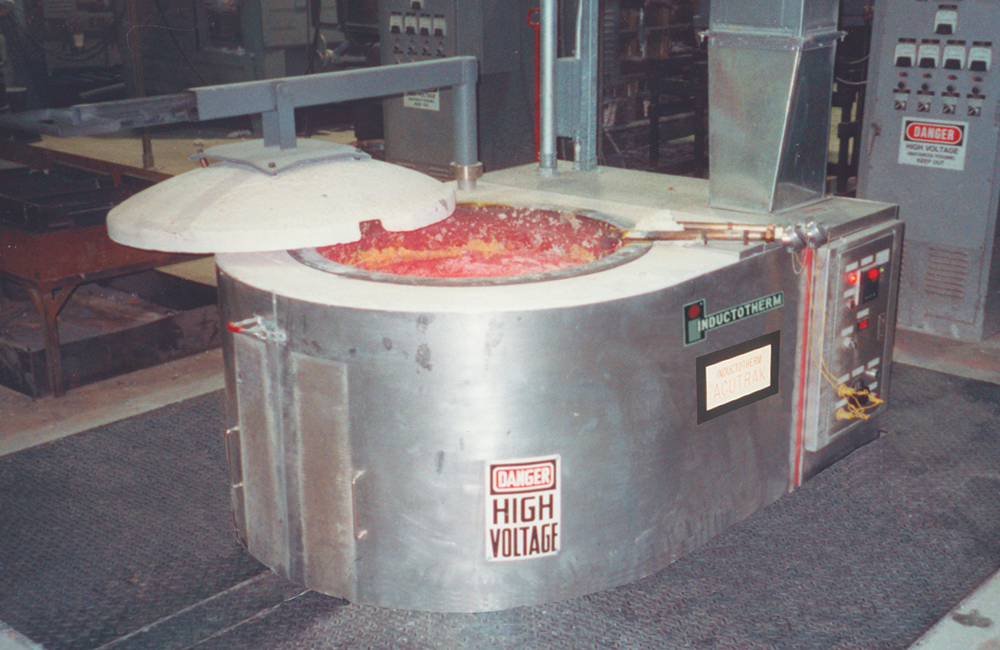

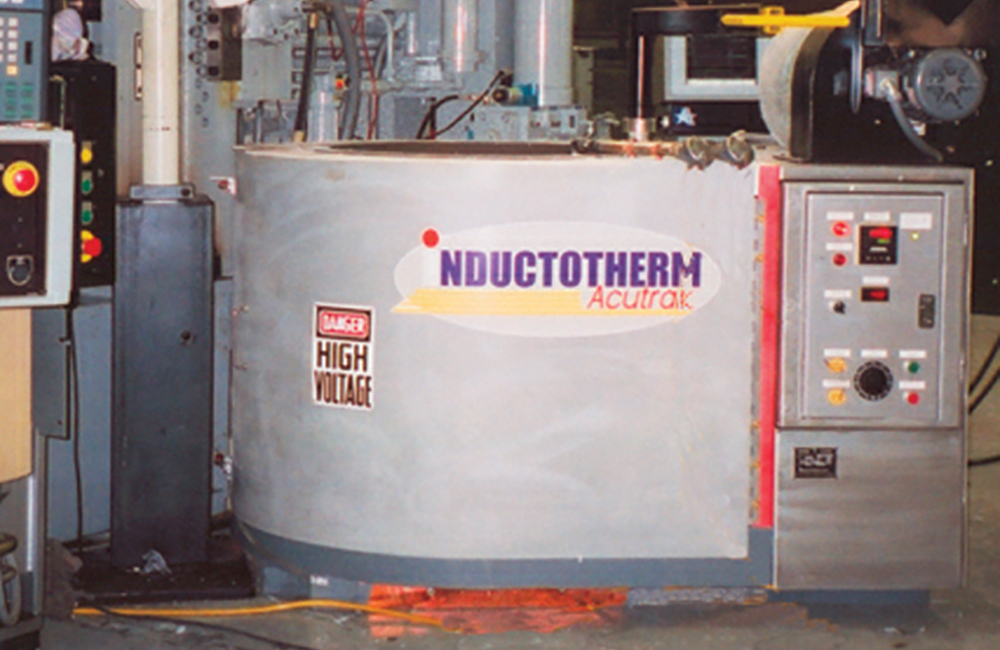

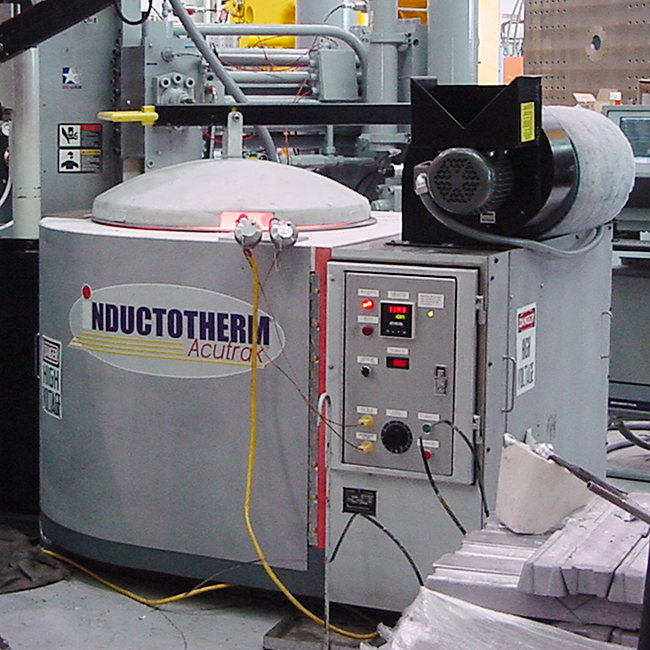

The Acutrak® Direct Electric Heat (DEH) System is an excellent furnace for aluminum melting.

These systems are well suited for die casting operations, permanent mold casting and for foundries. Direct Electric Heat Technology provides faster, cleaner and more efficient melting of aluminum and other nonferrous metals. These systems deliver energy more efficiently directly to the crucible and metal, making it less costly to operate than any furnace on the market today. Our unique aluminum melting and holding furnace uses an air-cooled, direct electric heating system that is more efficient and environmentally friendly than both gas-fired furnaces and resistance furnaces.

Acutrak® DEH Systems also assure more accurate temperature control of molten metal while eliminating water cooling. Energy losses are so low that even water cooling systems have become unnecessary and all components are air-cooled. An air blower is factory mounted or can be shipped separately for remote customer mounting.

Infographic

Infographic

Literature

Literature

Article

Article